The selection of auger feeders is mainly considered from the following aspects:

Different auger feeders for different materials.

1) When conveying powdery, granular, small block materials, the general shaft auger feeder should be selected for conveyance.

2) The shaft auger feeder should be selected for conveying large block materials.

3) For high temperature materials, water-cooled auger feeder (high temperature auger feeder) is available.

4) The shaftless screw conveyor can be selected for conveying viscous materials.

5) For some edible materials with strict hygiene requirements or corrosive materials, stainless steel auger feeder should be used.

Note:The auger feeders are not suitable for conveying explosive, flammable, toxic or corrosive materials.

The conveying output is the amount of material conveyed by the auger feeder per unit time. After selecting the corresponding type, the auger feeder needs to reach a certain conveying output. The delivery yield determines the diameter and blade spacing. Generally, the spiral blade and the diameter are equal, but different designs are required when different requirements are required. As the delivery yield increases, the helical diameter and blade spacing are also increased,so the auger feeder model will be larger.

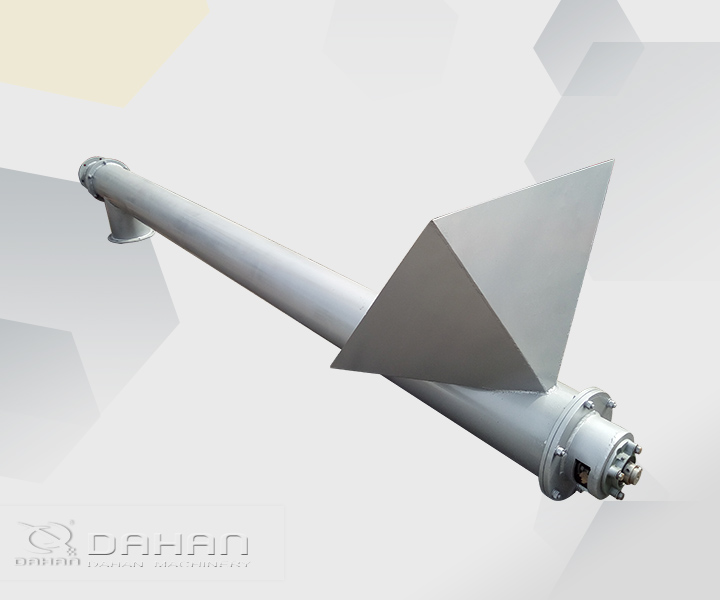

For horizontal conveying of materials, U-type/LS auger feeders are required, or tube-typeauger feeders are used according to the situation. When conveying materials obliquely, a tubularauger feeder is required.

1)Horizontal auger feeder: suitable length: ≤ 40 meters; can feed more than one point, multi-point cutting, the opposite point feed multiple points; can be made into U-shaped tank, with mixing, mixing, cooling Job function

2)nclined auger feeder: inclination angle: 0-60 degrees (depending on material and output), length of conveying length: ≤ 6 meters. (Users need to ask the data: the effective height of the lift, the material name, density, maximum feed size, throughput, delivery distance is limited)

3)Vertical auger feeder: length ≤ 15 meters; output: ≤ 50 tons; (effective height of lift, material name, bulk density, maximum feed size, throughput), this equipment is particularly strict for the materials transported, and Manufacturing standards are very demanding. (The manufacturing cost is slightly higher than the first two)

The equipment dimensions of theauger feeder include the screw conveyor width, diameter, length and motor reducer size, all of which directly affect the conveying capacity of the screw conveyor.

The feeder motor can use adjustable speed motor and ordinary motor to control the conveying speed and the hourly conveying volume. The larger the number of revolutions, the larger the conveying volume. Theauger feeder motor power is also related to the output and delivery angle, so when choosing the motor model and power, we need to determine the delivery yield of the screw conveyor and the angle of the conveyor.

The above is a discussion on how to choose theauger feeder, and choose a reasonableauger feeder model to help you improve efficiency and gain more profits in the process of transportation production.

If you have any other questions about auger feeder, feel free to give us a call and we would love to chat about it with you.

Write down your information and we will get back to you as soon as possible!

30 YEARS OF INDUSTRY EXPERIENCE